In accordance to our philosophy of using renewable and label-free raw materials, we have for the first time developed an organic binder resin that is free of pollutants and which is easy to process. Its composition differs fundamentally from existing furan or phenolic resin systems. Our PUROLiT completely avoids components such as formaldehyde, furfuryl alcohol, phenol, naphtha, furan and phenol resin and is therefore label-free and absolutely environmental compatible.

In addition to the positive processing properties, our PUROLiT makes it possible to positively change the emission profile caused by the moulding material, starting with the mould and core production and continuing through the entire process chain in the foundry.

Our development in cooperation with the University of Freiberg and experienced foundry partners has been able to demonstrate the easy applicability and high reliability in the area of manual mould and core production.

The binders of the PUROLiT series consist of two components (resin and hardener) whose reaction rate can be controlled via a catalyst. They are almost odourless, low-emission and therefore harmless to use. In addition to the processing-friendly properties, they have a high technical performance.

The environmental friendly properties qualify the separated core sands, for example, as non-hazardous waste materials according to the German Waste Disposal Ordinance.

For the first time, the user has a high-performance organic binder that makes foundry operations safer, environmental friendly and more cost-efficient.

Advantages PUROLiT:

- Applicable with all casting materials,

- Compatible with water and alcohol based coatings

- Safe and non-hazardous processing

- No harmful emissions during processing and afterwards,

- Odourless during mould/core production,

- Low binder requirement due to high bonding strength

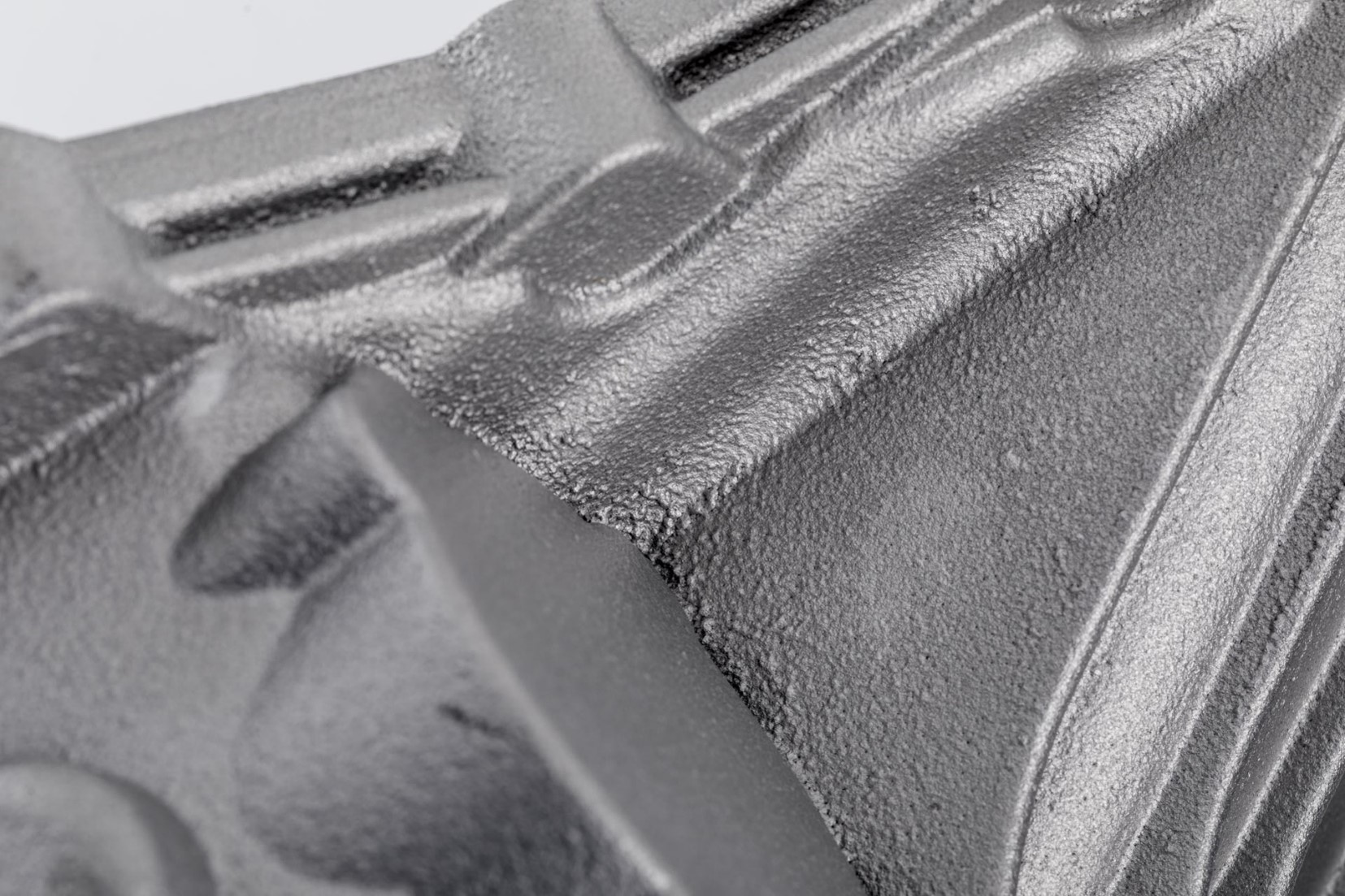

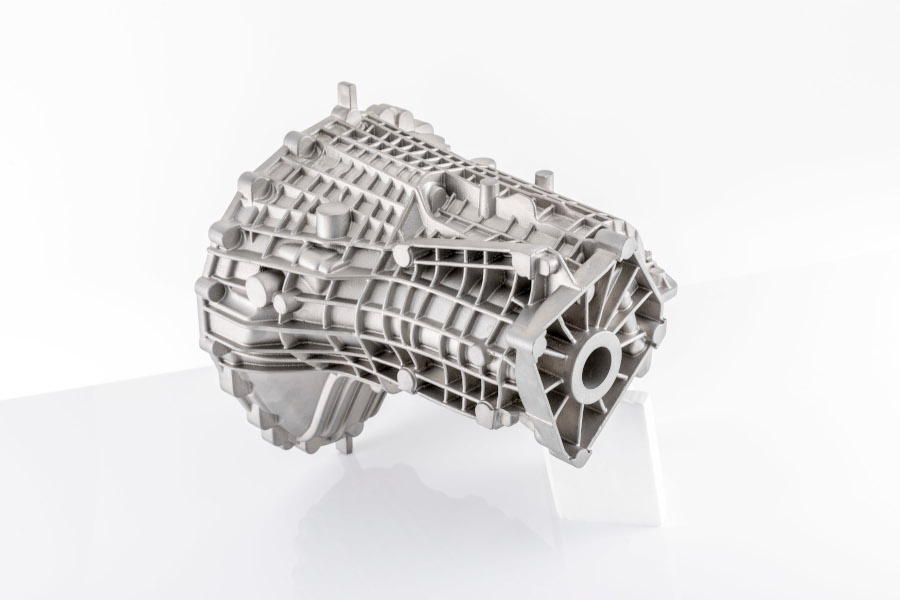

- Improved surface quality of castings when casting without coating

- No bale breakage during mould production

- Exact reproduction of deep and narrow contours

- Lower tendency to veining and hot cracking without additional additives

- Easy to process at room temperature

- Low viscosity and thus easy mixing of components,

- Easily controllable reactivity, depending on the application,

- No thermal post-curing required

- Cost-effective disposal of used sands

These advantages usually lead to a significantly improved casting quality with PUROLiT and thus significantly reduce the effort for a usually cost-intensive post-processing.

Take advantage of our PUROLiT from now on – we will be happy to inform you in detail.

With our many years of know-how as well as our own R&D department, we have always the possibility to make special adaptations to the individual conditions of your foundry in order to be able to fully meet your high expectations of our PUROLiT.