The moulding material of the future

Our innovative and environmentally friendly binders for the foundry industry

Our innovative and environmentally friendly binders for the foundry industry. Our company’s products comply with our own philosophy of the best possible conservation of resources and the environment. That is why we mainly use renewable and – in accordance with REACH – label-free raw materials for the production of our high-quality binder systems.

Revolution instead of evolution !

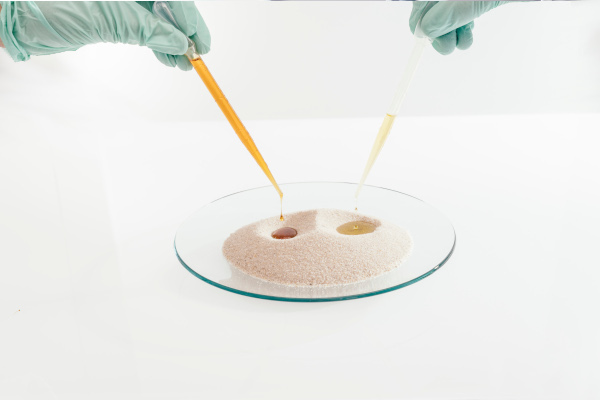

With this thinking in our mind, we have developed a fundamental alternative to the chemical binders that have been used almost unchanged in the foundry industry for over 50 years. As a result, we can already offer our customers 2 innovative binder systems for manual and machine mould and core production in combination with all common mould base materials.

Thanks to a careful selection of raw materials, as well as extensive tests in our laboratories both systems combine an outstanding environmental friendly behaviour with an enormously high technical performance at the same time.

We thus offer a genuine alternative that enables resource-saving, sustainable and environmental friendly mould and core production

Our PUROLiT is a chemically curing binder. The two-component system is cold self-curing and your alternative for currently used furan or phenol systems.

Environmental protection with every molecule

The motivation behind our developments over the last few years has been to be able to supply the foundry industry with exceptionally environmental friendly products. In this way, we support the industry’s transition to climate-neutral production.

To achieve this, we have reinvented the binder system for moulding material!

Modern plants

Our computer-controlled and automated production plant enables flexible, demand-oriented and resource-saving production.

Quality

Our promise to our customers is a guaranteed high quality of our products. Permanent quality control of all raw materials as well as our production ensures this promise.