Sustainability

A central challenge of the 21st century is to protect resources and the environment while at the same time promoting positive economic developments.

We have taken up this challenge with the development of our modern and innovative binders for the foundry industry.

The products of our company therefore correspond to our own philosophy of the best possible protection of resources and the environment. Therefore, mainly renewable and – according to REACH – label-free raw materials are used for the production of our polyurethane systems.

This already makes a clear difference.

If you look at the entire ecological footprint of a foundry binder, our PUROLiT crystallises Bindur’s understanding of sustainability. A consistent renunciation of toxic components that are harmful to health and the environment is a matter of course for a binder resin from our company. In combination with a reduction of emissions along the entire process chain of a foundry, low required binder amounts, good reclaimability as well as excellent landfillability, this results in a completely new reality for casting with lost moulds – a sustainable sand casting.

Emissions

A consistent reduction of emissions along the entire process chain of a foundry is a central aspect in the development of binders of the PUROLiT product range.

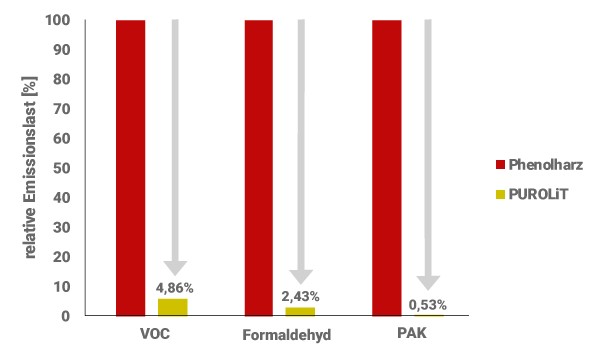

In emission measurements during mould and core production, for example, PUROLiT shows considerable advantages over conventional phenolic resin binders. The basis for this is the significantly different chemical composition of our PUROLiT compared to a conventional phenolic resin binder. The following figure illustrates this by an example.

We would be happy to consult with you individually and show you your personal optimisation potential based on your current moulding and core making process.

PUROLiT shows significantly lower values for volatile organic compounds (VOC), formaldehyde and polycyclic aromatic hydrocarbons (PAH) in the example shown. Furthermore, it could be proven that no isocyanates are released. This creates clear processing advantages for you and your employees.

The emission advantages are also clearly visible when PUROLiT moulding materials are cast with cast iron or aluminium. No important conductive components such as ammonia or nitrogen oxides could be detected in the exhaust air. Extensive analyses using GC/MS also show a drastically lower BTEX content in the emission profile compared to conventional binders.

PUROLiT is thus demonstrably significantly lower in emissions than previously used binders.

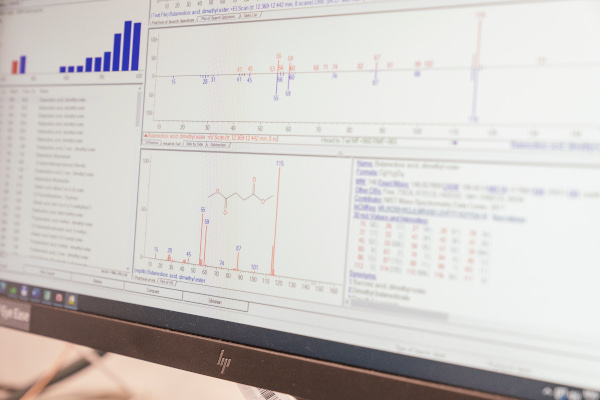

In order to be able to continue to set new standards and optimise the emission behaviour even further in the future, we have our own strong research and development department and use the most modern analytical methods in our laboratories.

Regenerability of used sands containing PUROLiT

Used sand containing PUROLiT can be easily reprocessed by mechanical and/or thermal regeneration with your existing aggregates. This means that it can be used as desired in a moulding material cycle.

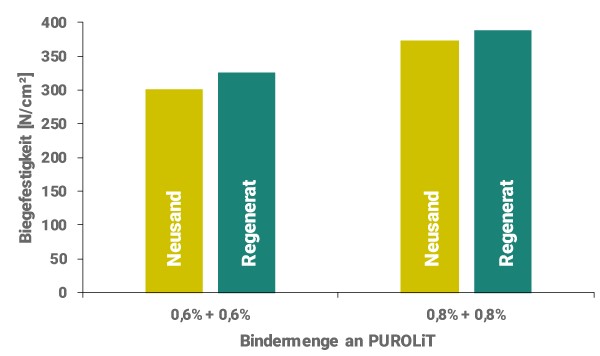

Extensive parameters were determined in tests at the Foundry Institute of the TU Bergakademie Freiberg. An important parameter for assessing the quality of the reclaimed sand is, for example, the bending strength that can be achieved using the reclaimed material. The following figure illustrates that when using mechanically regenerated sands, even higher strengths can be achieved than with new sand with the same amount of binder.

In addition to the pure reclaimability of the chemically bonded moulding material, the inflow of core sand plays a decisive role in the use of the binder system for the production of cores and the casting of the same in bentonite-bonded moulds.

Core sands which, after casting, flow wholly or partially into a clay-bonded circulating moulding material system must therefore meet special requirements.

Our environmentally friendly binder PUROLiT shows:

- a good chemical compatibility with green sand circulation systems,

- stable values even with high core sand inflow,

- easy mechanical and/or thermal regenerability.

We were able to test and prove this context in a large number of test series in our cooperation with the Foundry Institute of the TU Bergakademie Freiberg.

Landfilling

If reuse of the moulding material after regeneration is only possible or desired to a certain extent, landfilling of the remaining used sand becomes necessary.

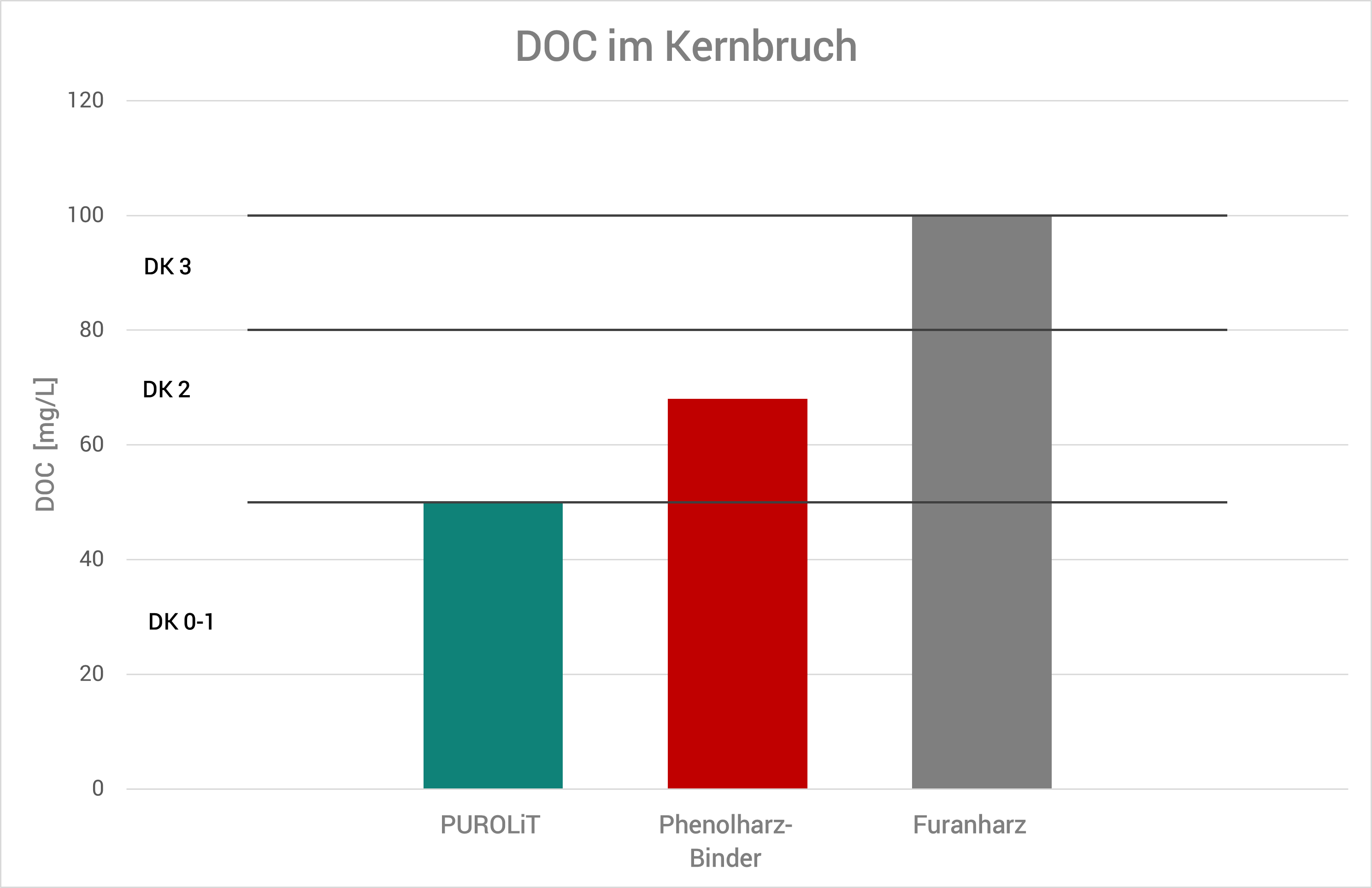

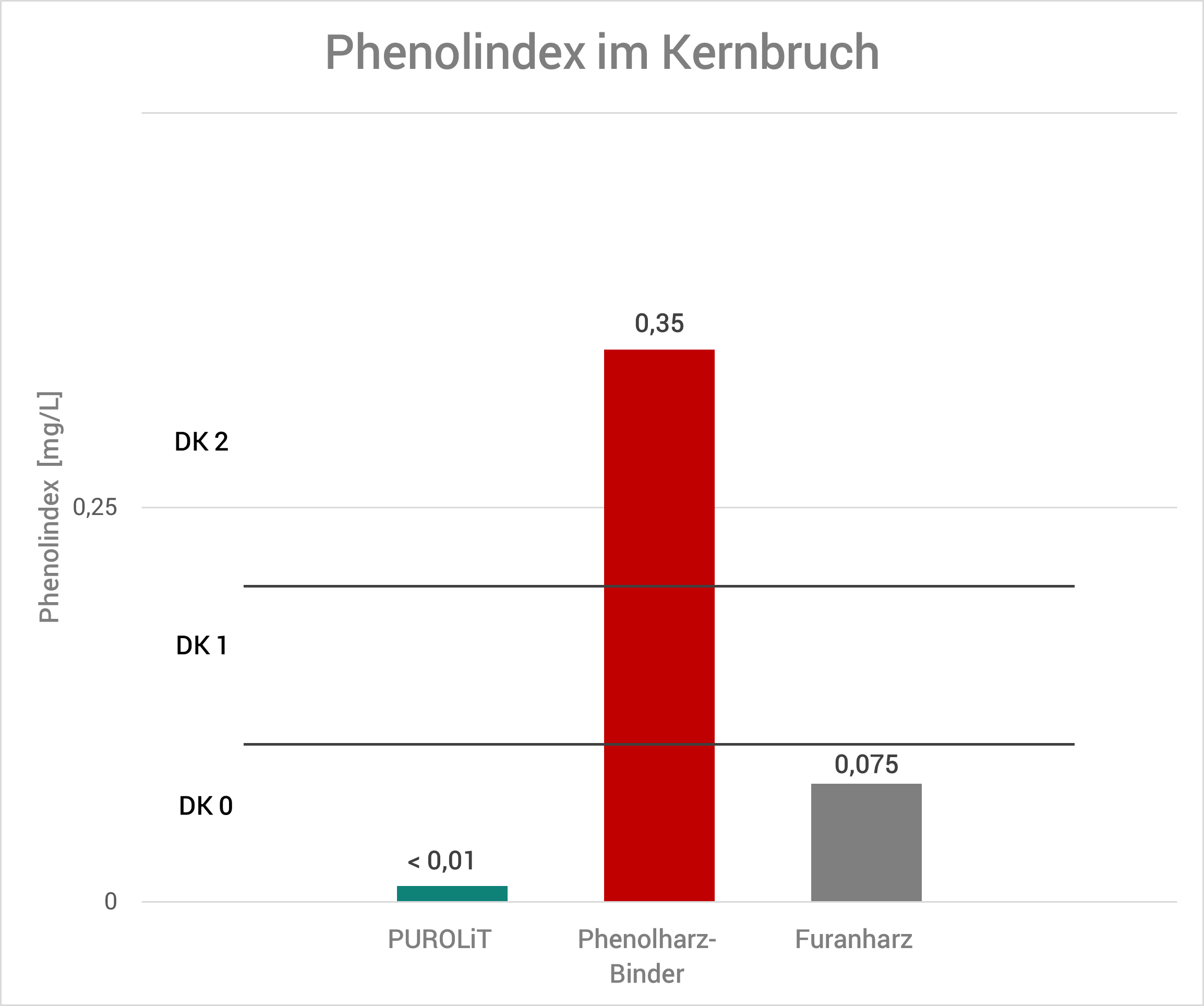

Used sand and broken cores containing PUROLiT can be landfilled much more cost-effectively, since the relevant parameters phenol index, DOC and contamination with aromatic hydrocarbons are greatly reduced compared to conventional binders. This is impressively illustrated in the following figure.

While used sands with commercially available phenolic or furan resins are assigned to landfill class 2, PUROLiT-bound used sand can already be classified in landfill class 0 or 1, depending on the binder quantity.

This means that our PUROLiT meets the requirements of an environmentally friendly moulding sand binder throughout the entire process chain of a foundry, right up to its discharge from the industrial production process.